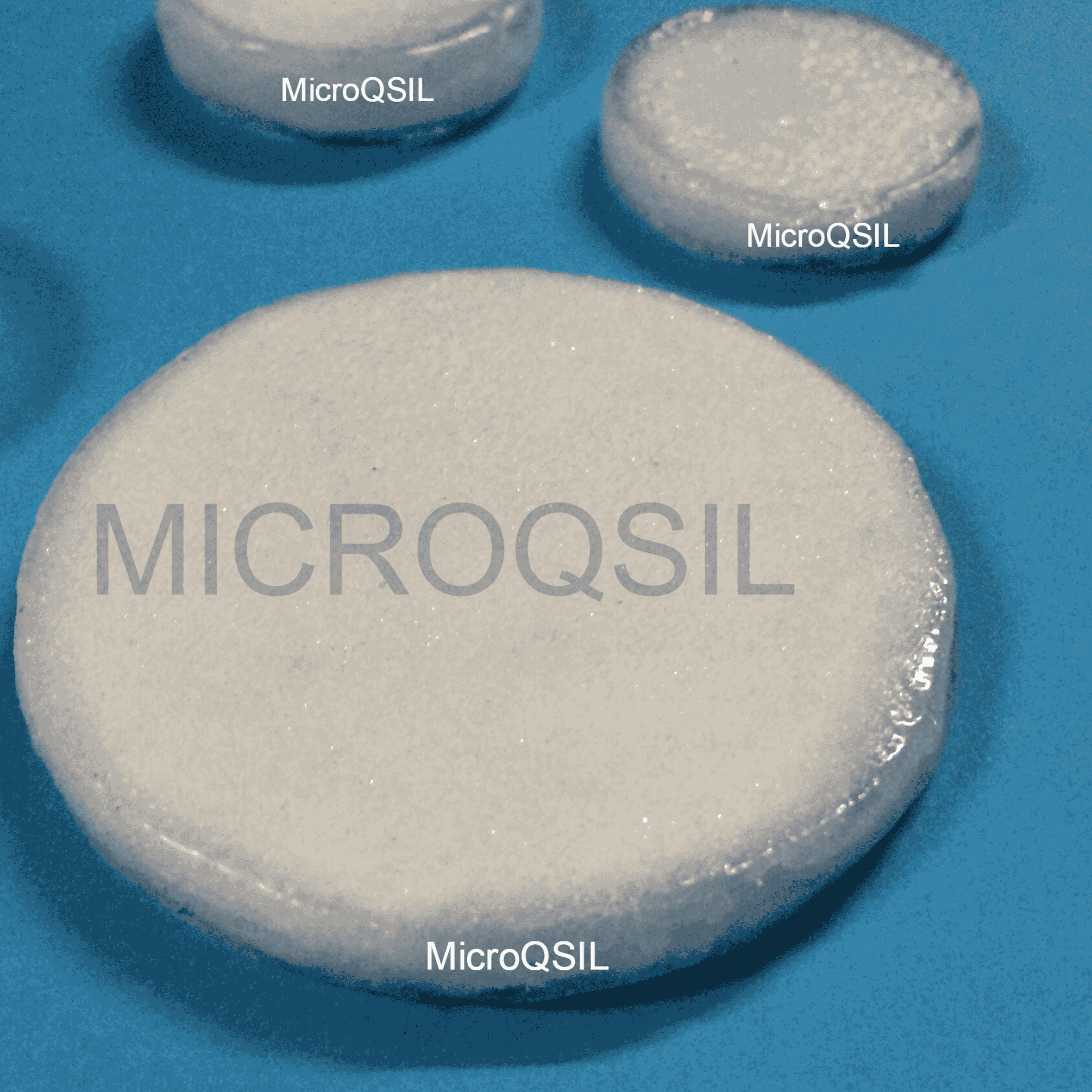

Quartz Fritted Disc / Quartz Sintered Disc

Quartz fritted discs, also called quartz sintered discs, are manufactured from premium fused silica (SiO₂ 99.99%). Designed for industries that demand purity, durability, and thermal stability, these discs deliver reliable performance in semiconductor processing, laboratory filtration, and high-temperature applications.

✔ Resistant to aggressive chemicals

✔ Excellent optical clarity

✔ Withstands temperatures up to 1100°C

✔ Available in multiple porosity grades

Standard Available Sizes

| Diameter (mm) | Thickness (mm) |

|---|---|

| 10 | 2–3 |

| 12 | 2–3 |

| 15 | 2–4 |

| 20 | 2–5 |

| 25 | 2–5 |

| 30 | 3–5 |

| 35 | 3–5 |

| Diameter (mm) | Thickness (mm) |

|---|---|

| 40 | 3–5 |

| 50 | 3–5 |

| 60 | 3–5 |

| 70 | 3–5 |

| 80 | 3–5 |

| 90 | 3–5 |

| 100 | 3–5 |

Technical Features – Quartz Fritted / Sintered Disc

| Porosity Grade | Pore Size (Microns) | Applications |

|---|---|---|

| 00 | 250 – 540 µm | Liquid and Gas Filtration |

| 00 | 150 – 240 µm | Filtration of coarse particulates, Gas Filtration |

| 1 | 100 – 150 µm | Coarse particulate filtration, Gas Distribution, Liquid Filtration, Coarse Gas Filtration |

| 2 | 60 – 100 µm | Fine Filtration |

| 3 | 15 – 60 µm | Fine Filtration, Analytical work with fine precipitates |

| 4 | 10 – 15 µm | Analytical work with very fine precipitates |

APPLICATIONS OF QUARTZ FRIT FILTER / SINTERED DISC

Semiconductor Industry

- Wafer processing and etching

- Diffusion and oxidation furnace components

- Gas filtration in cleanroom environments

Laboratory & Research

- Filtration of aggressive chemicals, acids, and solvents

- Support base in chromatography and Soxhlet extraction

- Gas dispersion in chemical reactions

- Catalyst support in experimental setups

High-Temperature Applications

- Furnace filters and thermal barrier components

- Filtration under extreme heat conditions (up to 1100°C)

- Hot gas and vapor filtration

Industrial Chemical Processes

- Filtration of corrosive liquids and gases

- Catalyst carriers in chemical reactors

- High-purity separation in pharmaceutical and biotech setups

Gas & Liquid Filtration Systems

- Ultra-fine particle removal

- Purification in analytical labs

- Dispersion of gases into liquids (bubblers, aerators)

Frequently Asked Questions

What is a Quartz Frit Filter (Sintered Disc)?

A quartz frit filter, also called a quartz sintered disc, is a high-purity fused quartz component used for fine filtration. It is manufactured by sintering quartz particles together, creating a porous structure that allows liquids or gases to pass through while trapping impurities.

What porosity grades are available in quartz frit filters?

Quartz fritted filters are available in porosity grades 00 to 4, covering pore sizes from 10 microns to 540 microns. This allows selection from coarse separation to ultra-fine particle retention.

What are the standard sizes of quartz frit filters?

Standard diameters range from 10 mm to 100 mm, with thickness options between 2 mm and 5 mm. Custom sizes and shapes can also be manufactured upon request.

How much temperature can a quartz frit filter withstand?

Quartz fritted discs are highly heat-resistant and can operate up to 1100°C in continuous use, making them suitable for high-temperature and thermal shock conditions.

Can quartz frit filters be customized?

Yes. Both diameter and thickness can be customized, and all porosity grades (00–4) can be manufactured to match specific application needs.

What is the difference between quartz frit filters and glass frit filters?

Quartz frit filters are made from fused quartz (SiO₂ 99.99%), which offers much higher purity, thermal resistance, and chemical stability compared to borosilicate glass frits. This makes them more suitable for demanding laboratory, semiconductor, and high-temperature applications.

Where can I buy quartz fritted discs?

Quartz frit filters are available directly from Microqsil at: https://microqsil.com/products/quartz-frit-filter