Quartz Discs, Windows & Sight Glasses – High Purity Fused Quartz

High Purity Quartz Disc is manufactured from premium fused (SiO₂ 99.99%), ensuring unmatched purity, optical clarity, and durability. Designed for industries where precision and reliability are critical, Semiconductor quartz discs withstand extreme temperatures, thermal shock, and aggressive chemical environments.

With customizable sizes and thicknesses, we supply custom quartz disc tailored to your exact application—whether in semiconductor processing, optical systems, laboratory setups, or high-temperature industrial equipment

Customization Option

- Diameter Range: 5 mm – 500 mm

- Thickness:5 mm – 50 mm

- Surface Finishes: Ground, polished, optical grade

- Edge Options: Beveled, rounded, fire-polished

- Tolerances: Diameter ±0.02 mm, Thickness ±0.01 mm

Our quartz discs provide several unique advantages:

- Ultra-High Purity (99.99% SiO₂): This ensures minimal contamination for sensitive processes.

Furthermore, it guarantees excellent results in semiconductor and optical applications. - Thermal Stability: Quartz discs remain stable up to 1100°C.

As a result, they perform reliably in furnaces and high-temperature systems. - Optical Transparency: They transmit across UV, visible, and IR ranges.

In addition, this makes them suitable for spectroscopy, laser optics, and scientific instruments. - Chemical Resistance: Resistant to acids and harsh chemicals.

Therefore, they are ideal for cleanroom and laboratory environments.

Applications

Semiconductor Industry

- Wafer processing, etching, and furnace components

- High-purity environment compatibility

Optical Instruments

- Lenses, windows, and sight glasses

- Optical lenses and windows in UV, Visible and IR systems

- Common in spectrometers, microscopes, and telescopes

High-Temperature & Thermal Applications

- Viewing ports and protective windows

- Common in Furnace, reactors and vacuum chambers

- Sight Glasses & Viewports

Laboratory & Industrial Equipment

- Chemical-resistant covers and plates

- Precision measuring instruments and sample holders

Laser Optics

- Laser windows, mirrors, and beam splitters

- Fused quartz can withstand high laser power and thermal loads

UV Applications

- Deep UV radiation (down to ~180 nm)

- Used in UV curing systems, Lithography

- Disinfection equipment, and solar simulators

Data Sheet

| Property | Value |

|---|---|

| Material Purity (SiO₂) | ≥ 99.99% |

| Density | 2.2 g/cm³ |

| Hardness (Mohs) | 7 |

| Thermal Expansion (20–300°C) | 0.55 × 10⁻⁶ /K |

| Continuous Use Temperature | 1100°C |

| Softening Point | 1665°C |

| Annealing Point | 1140°C |

| Refractive Index (589 nm) | 1.458 |

STANDARD SIZES TABLE

| DIAMETER (MM) | THICKNESS (MM) |

|---|---|

| 10 | 0.5 – 5.0 |

| 12 | 1.0 – 5.0 |

| 15 | 1.0 – 5.0 |

| 20 | 1.0 – 5.0 |

| 25 | 1.0 – 10.0 |

| 30 | 1.0 – 10.0 |

| 35 | 2.0 – 10.0 |

| 40 | 2.0 – 20.0 |

| 50 | 2.0 – 20.0 |

| DIAMETER (MM) | THICKNESS (MM) |

|---|---|

| 60 | 3.0 – 6.0 |

| 75 | 3.0 – 6.0 |

| 80 | 3.0 – 8.0 |

| 90 | 5.0 – 20.0 |

| 100 | 5.0 – 12.0 |

| 120 | 6.0 – 15.0 |

| 150 | 8.0 – 18.0 |

| 180 | 10.0 – 20.0 |

| 200 | 10.0 – 20.0 |

Our quartz discs and windows are manufactured in a wide range of standard sizes. Diameters include 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 75mm, 80mm, 90mm, 100mm, 120mm, 150mm, 180mm, and 200mm. Available thickness options cover 0.5mm, 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, and 20mm. For example, popular sizes include Quartz Disc 25mm x 1mm, Quartz Disc 25mm x 2mm, Quartz Disc 50mm x 3mm, Quartz Disc 100mm x 5mm, and Quartz Disc 150mm x 10mm. Custom diameters and thicknesses can also be produced upon request.

Quartz Disc Grades – JGS1, JGS2, JGS3

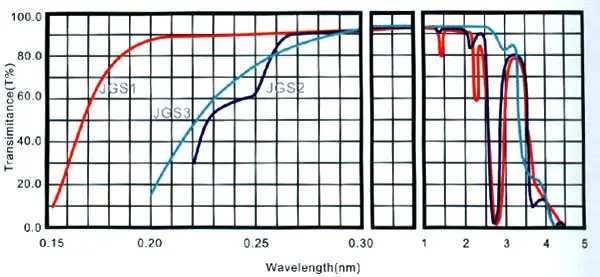

Microqsil offers high-purity fused quartz disc and quartz glass window in three distinct grades—JGS1, JGS2, and JGS3—to meet a wide range of optical and industrial needs. Each grade differs in UV and IR transmission, bubble content, and surface quality, allowing customers to select the best material for their application while maintaining excellent thermal stability and chemical resistance.

JGS1 – High UV Transmission

JGS1 quartz glass discs and quartz window are designed for maximum ultraviolet light transmission with extremely low bubble and inclusion content. They are ideal for UV optics, semiconductor photolithography, and scientific instruments that require precision and clarity down to 185 nm.

JGS2 – Standard Optical Grade

JGS2 quartz discs provide balanced performance across the UV, visible, and IR spectrum. This grade maintains good optical quality with moderate bubble content, making it a cost-effective choice for general laboratory quartz windows, viewports, and industrial optics between 200–2500 nm.

JGS3 – Infrared Grade

JGS3 quartz discs are optimized for extended infrared transmission, offering superior performance from the visible into the mid-IR region (up to ~3500 nm). With higher bubble tolerance but excellent IR clarity, they are suited for thermal imaging, sensor systems, and IR spectroscopy.

OPTICAL TRANSMISSION GRAPH

| Grade | UV Transmission | IR Transmission | Bubble/Inclusion Content | Typical Use |

|---|---|---|---|---|

| JGS1 | Highest (down to 185 nm) | Good up to 2500 nm | Very Low | UV optics, semiconductor, research instruments |

| JGS2 | Moderate (200 nm+) | Good up to 2500 nm | Low | General optics, windows, lab use |

| JGS3 | Limited UV | Best up to 3500 nm | Higher | Infrared optics, thermal imaging, sensors |

Frequently Asked Questions (FAQ) About Quartz Discs

A quartz disc (also called a quartz window) is a flat, polished piece of fused silica. It is highly pure, very strong and transmits light from UV to IR.

They are common in semiconductor processing and furnace components. In addition, they serve as windows, lenses and sight glasses in optical and lab equipment.

Standard sizes range from 10 mm to 200 mm in diameter with 1–10 mm thickness. Custom dimensions can also be supplied on request.

They withstand continuous heat up to 1,050 °C and short bursts up to 1,200 °C. Therefore, they are reliable for high-temperature systems.

Yes. They offer excellent transmission from deep UV to IR and, moreover, can be coated for even better optical performance.

Unlike regular glass, fused silica quartz discs can handle higher heat, have lower thermal expansion, and resist chemicals better. They also offer superior optical clarity, especially in the UV and IR spectrum.

Absolutely. Custom quartz discs can be made with specific diameters, thicknesses, drilled holes, edge polishing, or coatings depending on your requirements.

You can order both standard and custom quartz discs directly from MicroQsil, which supplies products worldwide.